In house research and development.

Research and development is critical to the continual improvement of the Powerdown range of ride control components.

This type of research is carried out utilizing some of the most advanced shock absorber testing facilities available through performance and durability tests, followed by testing our products in all types of diversified road and climatic conditions.

Many factors are taken into consideration when designing a shock absorber; vehicle application, suspension type, on and off highway use; whilst trying to achieve optimum comfort and control.

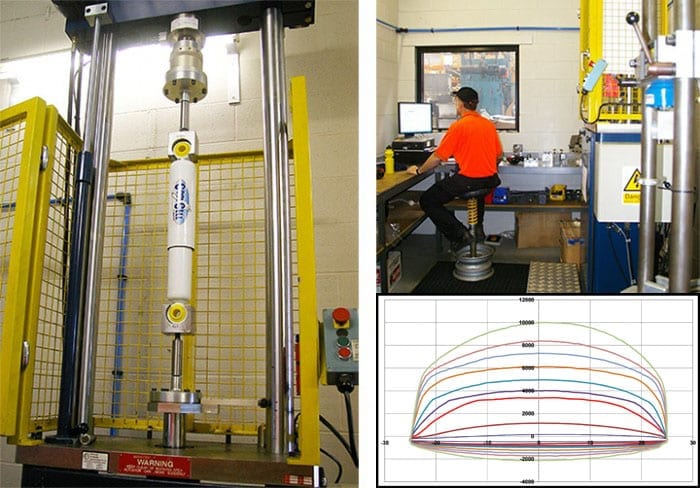

Supershock on Dyno

Our engineers and R&D team at Powerdown test all shocks using our variable stroke dynamometer. Data is fed through the computer to simulate corrugations and dipping dirt roads to work the shock absorber to it limitations. This data loop is then replayed multiple times to determine seal life and shock absorber fade at certain temperatures. The results of these dyno tests help our engineers develop better designed shocks for all conditions.